The Thor 9 Hammer Throw Cage is a unique Patent Design #9,889,366 B2 that is set to change the future of Hammer Throw cages.

Most hammer cages are easily susceptible to damage. Poles get dented and nets become torn by implement impact. Cages that have low wind ratings spend most of their life in an unusable condition because the net is lowered. Throwers are then limited to when they can train and the cage becomes labour intensive to make usable.

Our Thor 9 is a 9m high cage where this efficient setup makes use of only 3 support poles, leaving the ground area free from obstructions. This provides a clear view for spectators and also means the cage has minimal visual impact when not in use.

The 3 support poles are all on hinged base plates making installation even easier. The 7m high perimeter net is anchored with retaining ropes and is set away from the poles to reduce any chance of damage to the net and poles. The 9m high gates can be opened and closed easily with the gate ropes.

The Thor 9 cage is much cheaper to maintain than other types of cages. This cage is wind rating to 100 km/h which means that the nets can be left in place during strong winds unlike many other cages. Not having to lower and re-raise the nets constantly reduces the manpower required to manage the cage and ultimately reduces any ongoing cost.

Thor 9 is World Athletics Certified and is built for long term use.

Spec Summary:

9m high x 3.2m long gates that pivot 4.2m forward of circle centre. 7m high perimeter net. World Athletics certified, for non-stadium type venues

Play Hard Sports has two Athletic Hammer Throw Cages that will provide a better experience for everyone.

Both cages feature:

- Wind rated to 100 km/h – nets can remain erected in strong winds.

- Reduced number of support poles – for better vision and reduced risk of implement damage.

- Custom labels

- Choice of 12 colours (two pac gloss paint finish)

THOR 9 SPECIFICATIONS

| Size | 9m x 3m gates, 7 metre high perimeter. |

| Gate pivot distance | 4.2m from circle centre. |

| Gate edge | Rope and resin composite tube. |

| Gate operation | Swing arm open and closing ropes and snap hook at ground anchors. |

| No. of poles | 3 - Fewer support poles, which is more aesthetically pleasing. |

| Pole hardware | Rope disc cleats and pulley wheel. |

| Pole material | Combination of steel, aluminium and fibre composites. |

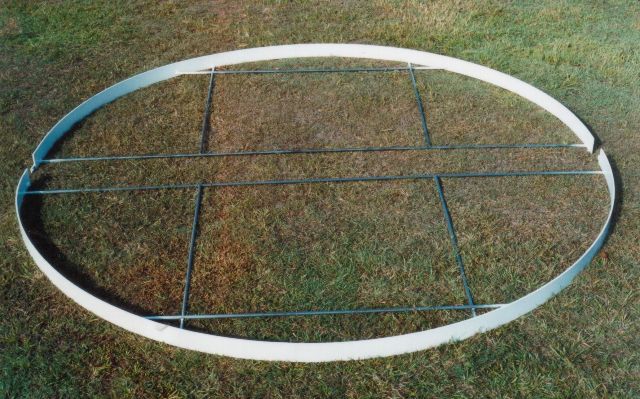

| Ground work | 3 sleeves and removable hinged base plates, 14 rope anchors |

| Finish | Choice of 12 colours (two pac gloss paint finish). |

| Net | 44mm square mesh, 5mm woven poly cord with 350kg breaking strain, black (green optional), UV stable, World Athletics certified. |

| Net support | Net rails all round. |

| Ropes | 8mm black woven polypropolyne. |

| Wind rating | Net can remain erected up to 100 km/h. |

| Assembly method | Poles are assembled on the ground and raised by hand pulley. |

| Manpower | 2 |

| Assemply time | 5 hours |

| Assembly equipment | Pulleys (provided), spanners M20 (3/4") & M12 (1/2'), knife, pliers. |

| Warranty | 5-year on hard structure and netting to World Athletics compliance |

| Compliance standard | NCAA compliant & World Athletics certified. E-15-0822 |

| United States (of America) Patent and Trademark Office (USPTO) | Patent #9,889,366 B2 |

Net Rails

Net height is consistent and reduces stretching.

Longer lasting nets

There is no metal frame around the gates for the hammer to impact and cause damage to the net.

Reduced risk of pole damage

Gate poles are positioned clear of the net so implements are captured before damage is caused.

High wind rating

Nets can remain erected all season which reduces labour operating time and cost.

Fewer support poles

Provides better spectator visibility and is more aesthetic pleasing.

Net tie back

Poles are positioned to avoid guide ropes being tied back.

Reduced installation cost

Less ground sleeves and footings to install.

Net retaining ropes

Ropes are easily tensioned to ground anchors.

Easy gate movement

The gate ropes clip onto ground anchors in the open, closed and discus positions.

Disc shaped cleats

Nets can not be hooked over cleats reducing net damage and keeping the net in the correct position.

Hinged poles

Poles are assembled laying down and raised with block and tackle (which is provided).

📌 Thor 9 Hammer Cage Locations

United Kingdom:

- Ashton Fields, Essex

- London Stadium

- Manchester Regional Arena

- Jarman Park Athletics

- Julie Rose Stadium

- Sutcliffe Park Athletics Track

- RAF Cosford Athletics Arena

- Grangemouth Sports Stadium

- Palmer Park Stadium

- Tipton Sports Academy

- Westcliff High School for Boys

- Alive West Norfolk

- Corby Athletics Club

- Costello Stadium

- Craigie Park Sports Development

- King Edwards School, Birmingham

- Pitreavie Athletics Track, Scotland

- The Bridge Leisure Centre

- Withdean Sports Complex

- Meadowmill Sports Centre

- Antrim Forum Stadium

- Colchester Garrison, Essex

- Down Grange Sports Complex, Hampshire

- Oxford University Sport, Oxford

- Saffron Lane Athletics Stadium, Midlands

International/Europe:

- FB Playing Fields, Jersey (Channel Islands)

- Footes Lane Athletics Track, Guernsey (Channel Islands)

QLD:

- Helensvale State High School, Gold Coast

- Somerset College, Gold Coast

- Ipswich & District Athletics Centre

- Bill Paterson Oval, Limestone Park

NSW:

- Fearney Dawes Athletic Centre, Newcastle

VIC:

- Alexandra Park Athletics, Albury

- Harold Stevens Athletics, Coburg

- John Landy Field, Geelong

- Victorian University

- Hagenauer Res Athletics Track, Box Hill

- Craigieburn Athletics Track (Sprint Athletics Centre)

TESTIMONIALS

Play Hard Sports Equipment (PHS) installed all Throw cages - as per the CCQ SP2 Program. All staff were present and available for asset management at the 2018 Australian Athletics Championships 15-18 February and XXI Commonwealth Games Gold Coast competition 25 March – 14 April. During those two major events Play Hard Sports Equipment (PHS) provided support with multiple installations and removal of the main track cage before and after the 2018 Australian Athletics Championships, the main XXI Commonwealth Games Gold Coast competition days and closing ceremony - in accordance with specified transition timeframes. It was an absolute pleasure to work with Trevor Bowman, Steve Dart and the entire Play Hard Sports Equipment team who collaborated effortlessly and displayed superior responsiveness and great team work to deliver this project without any delays. We have really enjoyed working with such a dynamic team and look forward to more great partnerships in the coming years.

“Whilst our Queensland office has been using your firm for a couple of years until recently the Victorian office had been using a local manufacturer. We curtailed that relationship and put in our first orders to you for a project we have just completed at the Glencairn Tennis Club. I viewed the completed project this morning and I have to say I am particularly impressed with the quality of the tennis playing infrastructure you provided and how good it looked. Thanks for the excellent service to date and we look forward to supporting your firm into the future”.

“As part of a complete rebuild of the Bill Stewart Athletics track in East Burwood, Victoria, we had a Play Hard hammer cage installed. During a thorough investigation of all cages available we decided that the Play Hard cage was second to none. Built for Australian conditions and made of a galvanized steel construction, with square netting making it easier to see through, and the simplicity of the front gates operation. It was clear that the Play Hard cage was the only choice. We made a conscious effort as a committee to buy Australian-made wherever possible, and not only Play Hard’s price is more than competitive, their products stand up against the best in the world. Everything that we purchased from Play Hard is of a robust construction and quality, built to outlast the others and for those reasons we could not be happier”

“The Townsville Sports Reserve is one of the nation’s premier locations for track and field athletics. Situated in a naturally beautiful region the venue is centrally located, easily accessible and affordable. The state of the art facilities provides an unparalleled and world class experience to athletes and fans alike. The latest addition to these facilities, a brand spanking new design Thor 10 throwing cage, manufactured by Play Hard Sports Equipment Australia and IAAF certified, saw its first national record last weekend when Brisbane’s Matthew Denny threw 80.48m to set a new Under 20 hammer record. The new cage received rave reviews. With facilities like these it’s no wonder the Townsville Sports Reserve has carved its niche as one of Australia’s hottest track and field destinations.”